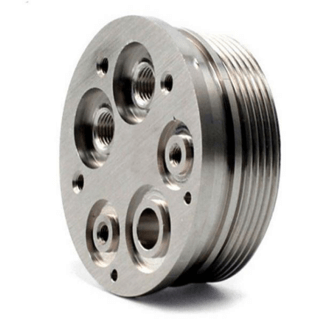

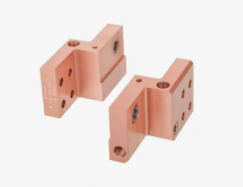

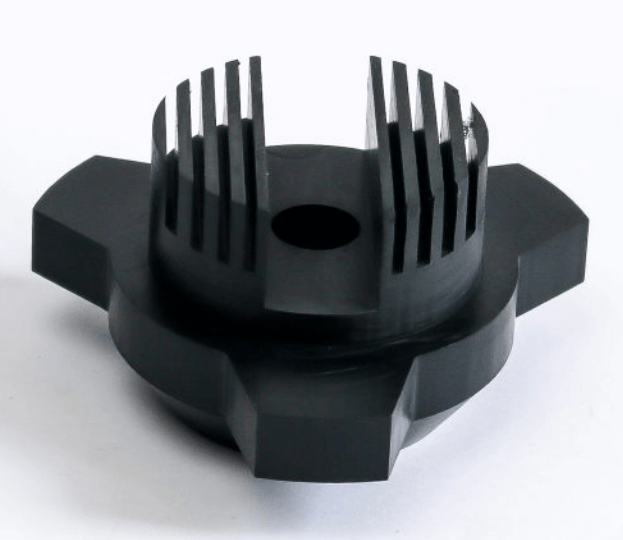

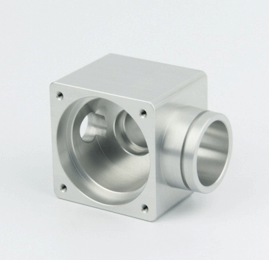

Precision CNC Machining

A wide range of metals for CNC machining, with applications in multiple industries. Promise Technology has strong CNC Machining capabilities, rich experience, and provides customized solutions.

Aluminum is one of the most known and used metals due to its efficient characteristics in many production processes. It is a metal with excellent hardness and flexibility at the same time.